ISO 7864 is the core international standard governing sterile hypodermic needles for single use. It defines both performance requirements and verified test methods to ensure safety, consistency, and functionality in clinical use. From a quality and regulatory perspective, ISO 7864 connects product design, material selection, and mechanical performance through objective testing.

For manufacturers, medical device laboratories, and inspection agencies, ISO 7864 provides a structured framework to evaluate needle strength, penetration behavior, bonding reliability, and fluid delivery performance. These parameters directly affect user safety, patient comfort, and compliance with global regulatory expectations.

Within hypodermic needle testing, ISO 7864 emphasizes mechanical integrity and functional performance. The standard addresses how a needle penetrates tissue-like substrates, how securely it bonds to the hub, and how effectively it delivers fluids. Each test targets a specific risk associated with needle use, such as excessive insertion pain, detachment from the hub, or restricted flow.

Testing according to ISO 7864 ensures that hypodermic needles perform consistently across batches and manufacturing sites, which is especially important for high-volume disposable medical devices.

One of the most critical procedures described in ISO 7864 is the needle penetration test. This method measures the force required for a needle to enter a standardized substrate at a constant speed. The resulting force–displacement curve provides two key indicators:

Force de pénétration maximale, representing the maximum resistance during initial entry

Force de traînée, reflecting friction as the needle continues through the substrate

Controlled measurement of force de pénétration helps manufacturers optimize needle geometry, tip sharpness, and surface finish. Excessive penetration force may increase patient discomfort, while insufficient force consistency may indicate variability in grinding or polishing processes.

A dedicated Strength Tester equipped with a high-resolution load cell ensures reliable force measurement and repeatable results. Modern systems allow precise speed control and continuous force recording, which supports both development and routine quality control.

Le fragmentation test for medical needles focuses on structural safety. During insertion and withdrawal, a needle must remain intact without shedding fragments that could remain in tissue. ISO 7864 includes requirements to verify that the needle maintains its integrity under defined mechanical conditions.

This test supports risk reduction in clinical use and confirms that material quality, heat treatment, and manufacturing processes meet the expected safety threshold. Fragmentation results also provide valuable feedback during supplier qualification and process validation.

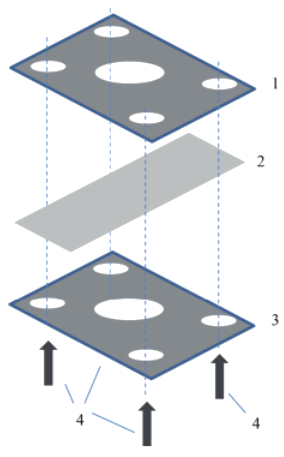

Needle Bond strength represents the mechanical connection between the needle tube and the hub. ISO 7864 specifies a tensile test method to confirm that this bond withstands defined loads without separation or failure.

Using a calibrated tensile Strength Tester, the needle is pulled axially at a controlled speed until separation occurs or a maximum force is reached. The recorded value reflects the bonding strength and indicates whether the selected adhesive or bonding process is suitable for the needle size and application.

Reliable needle bond performance is essential for preventing accidental detachment during injection, which could cause serious safety incidents.

Cet instrument applique avec précision un vide contrôlé à la seringue, ce qui permet un contrôle précis des variations de pression et de l'intégrité du piston. Conçu avec des connexions compatibles avec la norme ISO 80369-7 et des mécanismes de serrage sûrs, le SLT-01 garantit une évaluation complète de l'étanchéité à l'air et de la rétention du bouchon du piston.

Il utilise un système mécanique de haute précision pour mesurer les forces de décollement et de glissement pendant l'expulsion du liquide. Le MST-01 permet aux fabricants de quantifier la résistance à l'amorçage et au déplacement, fournissant ainsi des données essentielles pour garantir un mouvement fluide et constant du piston, indispensable pour assurer la sécurité et le confort.

Ce dispositif simule la pression à l'intérieur du corps de la seringue tout en appliquant des charges latérales et axiales au piston, reproduisant fidèlement les conditions d'utilisation clinique. Le SSPT-01 est conçu pour détecter les défaillances de joints les plus subtiles, aidant ainsi les fabricants à vérifier la fiabilité de leurs produits et leur conformité aux normes de sécurité les plus strictes.

In addition to mechanical strength, ISO 7864 addresses functional performance through the flow rate through the needle test. This evaluation confirms that the internal lumen allows fluids to pass at an expected rate under defined conditions.

Flow rate results relate closely to inner diameter consistency, surface finish, and cleanliness. A stable and predictable flow rate ensures accurate dosing and smooth injection, particularly in applications involving viscous pharmaceutical formulations.

To meet ISO 7864 efficiently, laboratories increasingly rely on integrated testing platforms. A modern Needle Penetration and Drag Force Tester from Instruments cellulaires combines penetration force measurement, drag force analysis, and flexible fixture design in a single system. Such solutions support standardized testing while allowing customization for specific needle types or customer requirements.

Automation options further improve repeatability, reduce operator influence, and support high-throughput testing environments. These advantages align well with ISO 7864 objectives and modern quality management systems.

ISO 7864 establishes a comprehensive technical foundation for evaluating sterile hypodermic needles. Through structured hypodermic needle testing, including needle penetration test procedures, penetration force analysis, Needle Bond strength verification, fragmentation test for medical needles, and flow rate through the needle test, manufacturers can ensure safety, performance, and regulatory compliance.

By adopting advanced testing solutions such as the Instruments cellulaires Needle Penetration and Drag Force Tester, organizations can improve data reliability, streamline quality control, and confidently meet ISO 7864 requirements across the full product lifecycle.