Needle Stiffness Test in Medical Device Quality Control

The needle stiffness test plays a critical role in ensuring the safety, reliability, and performance of medical needles used in syringes and other invasive devices. In daily clinical use, a needle must resist excessive bending while maintaining patient comfort and procedural accuracy. If stiffness is too low, the needle may deflect during insertion; if too high, it may increase the risk of tissue damage. Therefore, the needle stiffness test serves as a key mechanical evaluation in medical device manufacturing and quality assurance.

For manufacturers and quality inspection agencies, this test is not only a technical requirement but also a regulatory necessity. Standards-based needle testing helps demonstrate compliance, consistency, and product reliability throughout the production lifecycle.

ISO 9626 Requirements for Needle Stiffness Test

Understanding ISO 9626 in Needle Testing

ISO 9626 specifies requirements and test methods for rigid stainless steel needle tubing used in medical devices primarily intended for human use. The standard defines dimensional tolerances, mechanical properties, and testing procedures that ensure tubing performance before it becomes part of a finished needle.

Within ISO 9626, the needle stiffness test focuses on evaluating the resistance of stainless steel needle tubing to bending under a defined load. The method uses a three-point bending principle, where a controlled force is applied at the center of a supported tube span, and the resulting deflection is measured with high precision.

This approach allows manufacturers to confirm that stainless steel needle test results fall within acceptable limits for different gauges and wall thicknesses, ensuring consistent mechanical behavior.

Principle and Significance of the Needle Stiffness Test

How the Test Works

In a standard needle stiffness test, the tubing is supported at both ends over a specified span. A downward force is then applied at the midpoint using a defined loading geometry. The measured deflection directly reflects the stiffness of the tubing.

This needle test method offers several advantages:

- It provides quantitative and repeatable results

- It reflects real-world mechanical stresses during use

- It allows comparison across different needle sizes and wall types

Because the method directly relates force and deflection, it helps manufacturers identify deviations caused by material variation, heat treatment, or dimensional inconsistency.

Stainless Steel Needle Test Beyond Stiffness

Resistance to Breakage and Durability

In addition to stiffness, ISO 9626 includes tests for resistance to breakage. These evaluations simulate repeated bending cycles to verify that the tubing does not fracture under normal handling conditions. Together with the needle stiffness test, breakage testing offers a more complete picture of mechanical durability.

Corrosion Resistance Test Importance

The corrosion resistance test is another essential component of stainless steel needle testing. In this method, needle tubing is partially immersed in a sodium chloride solution for a defined period and then visually inspected. Any corrosion on the immersed section indicates potential risks for clinical safety and long-term storage.

Corrosion resistance testing ensures that stainless steel needles maintain surface integrity, prevent contamination, and meet hygiene expectations in medical environments.

Practical Value of Needle Stiffness Test Results

Accurate needle stiffness test data supports:

- Design validation of new needle products

- Incoming inspection of stainless steel needle tubing

- Process optimization during manufacturing

- Regulatory submissions and audits

For quality control personnel, consistent test results help reduce batch-to-batch variation and strengthen confidence in finished medical devices.

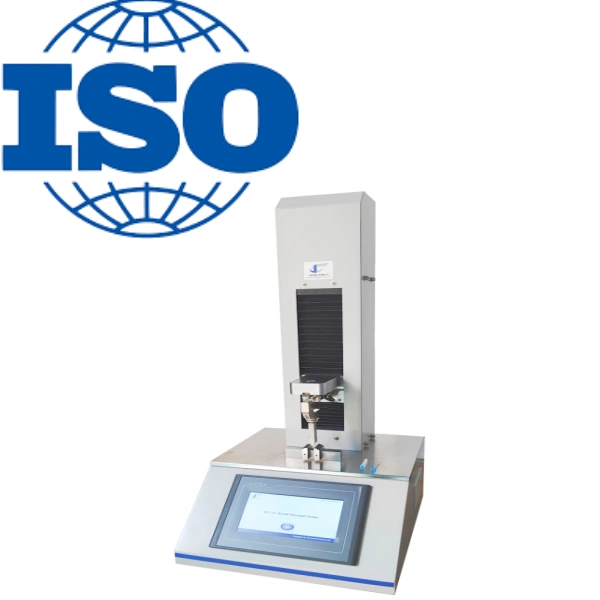

Advanced Needle Testing Solutions from Cell Instruments

As a professional manufacturer of materials testing instruments, Cell Instruments provides specialized solutions for needle stiffness test applications. Our syringe needle stiffness testers are designed to align closely with ISO 9626 requirements while offering practical advantages for laboratory and production environments.

Key strengths include:

- High-precision force and displacement measurement

- Stable mechanical structure suitable for micro-scale needle test conditions

- Flexible configurations to support different needle sizes and testing needs

Beyond standard equipment, Cell Instruments also supports customized testing requirements, automation upgrades, and integration into quality management workflows. This capability helps medical device manufacturers improve efficiency while maintaining compliance.

The needle stiffness test remains a cornerstone of mechanical evaluation for medical stainless steel needles. When combined with corrosion resistance testing and breakage assessment, it ensures that needle tubing meets both functional and regulatory expectations defined by ISO 9626. With reliable testing methods and professional instrumentation from Cell Instruments, manufacturers and laboratories can achieve consistent quality, safer products, and stronger market confidence.